In the complex and fast-paced world of logistics, a silent hero works tirelessly behind the scenes: the plastic pallet. For decades, wooden pallets dominated the supply chain, but the advent of plastic alternatives has revolutionized the way goods are stored, transported, and managed. Lighter, more durable, and more hygienic than their wooden counterparts, plastic pallets have become a critical component of modern logistics, and their journey from raw material to a workhorse of the global economy is a testament to the power of innovation. This comprehensive article will explore the rise of the plastic pallet, examining its manufacturing, its key advantages over wood, its diverse applications, and its role in creating a more efficient and sustainable supply chain.

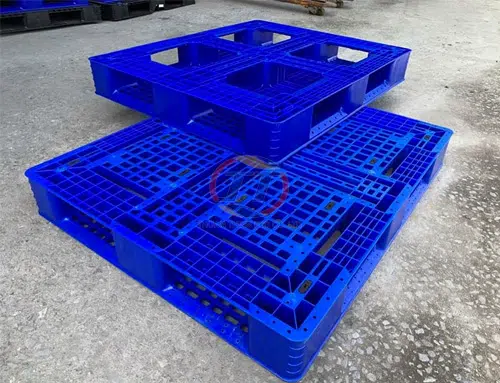

The plastic pallet is more than just a platform for moving goods; it is a symbol of a shift towards a more modern and efficient logistics system. Its smooth, non-porous surface makes it a safer and cleaner alternative to wood, which can splinter, absorb moisture, and harbor bacteria. Its consistent dimensions and light weight make it ideal for automated systems and international shipping, where every pound and inch matters.

The Making of a Pallet: From Resin to Rigidity

The manufacturing of plastic pallets is a sophisticated process that uses advanced molding techniques to create a product that is both strong and lightweight.

Injection Molding: This is the most common method for making plastic pallets. In this process, heated plastic resin is injected into a mold, where it cools and solidifies into the final pallet shape. This method allows for the creation of a seamless, durable, and precisely engineered product with a consistent weight and dimension.

Structural Foam Molding: This technique is used to create pallets with a cellular core, which makes them lighter and more rigid. This method involves injecting a plastic resin mixed with a blowing agent into a mold, which creates a foamed structure with a solid outer skin.

Material Selection: High-density polyethylene (HDPE) is the most common material used for plastic pallets due to its excellent impact resistance, chemical resistance, and ability to withstand a wide range of temperatures. Recycled plastic is also a key material, allowing for a more sustainable product.

The Advantages of Plastic Over Wood

The shift from wood to plastic pallets is driven by a number of significant advantages.

Durability and Longevity: A plastic pallet can last for more than 10 years, with a lifespan that is often 10 times longer than that of a wooden pallet. This reduces the need for frequent replacements and can lead to significant cost savings in the long run. Plastic pallets are also resistant to rot, corrosion, and insects.

Hygiene and Cleanliness: The non-porous surface of a plastic pallet makes it incredibly easy to clean and sanitize, which is a critical feature for industries like food processing, pharmaceuticals, and medical devices. Unlike wood, plastic does not absorb moisture, which can lead to mold and bacterial growth.

Sustainability: Plastic pallets are a more sustainable choice than wood. They are reusable, recyclable, and help to reduce the demand for cutting down trees. Their light weight also reduces fuel consumption and carbon emissions during transport.

Applications in a Modern Supply Chain

The benefits of plastic pallets have made them an ideal choice for a wide range of applications.

Food and Beverage: In the food and beverage industry, plastic pallets are used to transport and store everything from fresh produce to bottled water. Their hygienic properties are essential for preventing cross-contamination and ensuring product safety.

Pharmaceuticals and Medical: In the pharmaceutical and medical industries, where sterility is paramount, plastic pallets are the only option. Their smooth, non-porous surface can be easily cleaned and sanitized, and their durability ensures that fragile products are protected during transit.

Retail and Logistics: In the retail and logistics sector, plastic pallets are used to organize and transport goods within a warehouse and from a warehouse to a store. Their consistent dimensions and light weight make them ideal for automated systems and efficient space utilization.

In conclusion, the plastic pallet is a quiet but vital part of the global economy. Its journey from a niche product to a workhorse of the logistics industry is a testament to its durability, hygiene, and efficiency. As companies continue to seek ways to optimize their supply chains and reduce their environmental footprint, the plastic pallet will play an increasingly important role in shaping a more sustainable and productive future.