Behind every plastic product—from the bottle of water in our hand to the dashboard of a car—lies a story of raw materials, chemical engineering, and meticulous manufacturing. Plastic is not a single material but a vast family of polymers, each with its own unique properties, applications, and environmental footprint. Understanding the raw materials of plastics is the first step to understanding the products they become. This comprehensive article will serve as a primer on plastic raw materials, exploring the most common types, their characteristics, the processes that transform them, and the critical role they play in the global economy.

The journey of plastic begins with a polymer, a long chain of repeating molecular units called monomers. These polymers are typically derived from fossil fuels, such as crude oil and natural gas, but are increasingly being produced from renewable resources. The polymer is then processed into a variety of raw material forms, such as pellets, powders, and flakes, which are then used by manufacturers to create finished products.

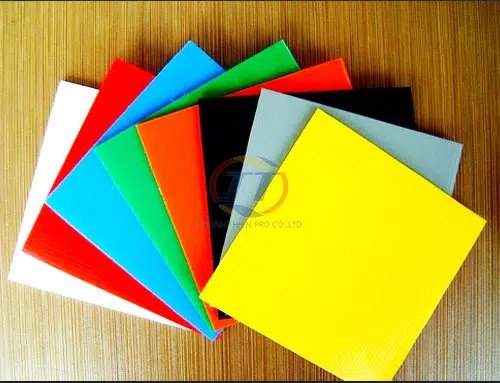

The Most Common Plastic Raw Materials: A Detailed Look

The world of plastic raw materials is dominated by a few key types, each with its own set of characteristics and uses.

Polyethylene (PE): This is the most widely produced plastic in the world. It is known for its light weight, durability, and resistance to chemicals. It comes in two main forms:

- High-Density Polyethylene (HDPE): A rigid and strong plastic used for milk jugs, water pipes, and detergent bottles.

- Low-Density Polyethylene (LDPE): A more flexible and transparent plastic used for plastic bags, food wraps, and flexible tubing.

Polypropylene (PP): This plastic is known for its high melting point and excellent chemical resistance, making it ideal for a wide range of applications, including food containers, automotive parts, and industrial fibers.

Polyethylene Terephthalate (PET): This plastic is known for its clarity, strength, and ability to hold carbonation. It is most commonly used for beverage bottles, but it is also used for a variety of other applications, including food packaging and polyester fibers.

Polyvinyl Chloride (PVC): This plastic is known for its rigidity and resistance to moisture and chemicals. It is used for a wide range of products, including pipes, electrical cables, and window frames.

Polystyrene (PS): This plastic is known for its light weight and ability to be foamed, making it ideal for packaging materials like Styrofoam, as well as for disposable cutlery and food containers.

The Manufacturing Process: From Pellets to Products

Once the raw plastic material has been produced, it is sent to manufacturers who use a variety of processes to transform it into finished products.

Injection Molding: This is the most common method for manufacturing plastic products. In this process, heated plastic pellets are injected into a mold, where they cool and solidify into the desired shape. This method is used to create everything from plastic containers and bottle caps to automotive parts and consumer goods.

Extrusion: In this process, heated plastic is forced through a die to create a long, continuous shape, such as a pipe, a sheet, or a film. This method is used to produce a wide range of products, including plastic sheets, plastic pipes, and plastic films.

Blow Molding: This process is used to create hollow plastic containers. A heated plastic tube is inflated with compressed air inside a mold, where it takes on the shape of the mold. This method is used to create a wide range of products, including plastic bottles, jugs, and drums.

The Role of Plastic Raw Materials in a Circular Economy

As the world grapples with the environmental impact of plastics, there is a growing focus on creating a circular economy, where plastic is reused, recycled, and repurposed rather than discarded.

Recycling and Repurposing: Many plastic raw materials, such as PET, HDPE, and PP, are highly recyclable. They can be melted down and reprocessed into new products, reducing the demand for virgin plastic and diverting waste from landfills.

Bio-based Plastics: The development of bio-based plastics, which are made from renewable resources like corn, sugarcane, and algae, offers a sustainable alternative to traditional plastics. These materials have a smaller carbon footprint and can be a key part of a more sustainable future.

In conclusion, plastic raw materials are the building blocks of a vast and diverse industry. By understanding the different types of plastics, the processes that transform them, and their role in a circular economy, we can make more informed choices about the products we use and help to build a more sustainable future.