In the relentless world of industrial logistics, efficiency is the name of the game. Every second saved, every error eliminated, and every inch of space optimized can translate into millions of dollars in savings and a significant competitive advantage. For decades, the logistics industry relied on manual processes, paper-based records, and human-driven decisions. But today, a revolution is underway, driven by a new generation of smart technologies that are transforming warehouses from simple storage facilities into intelligent, interconnected hubs of commerce. This comprehensive article will explore how technology is revolutionizing industrial logistics, with a focus on a key innovation: the Warehouse Management System (WMS).

A Warehouse Management System is the brain of the warehouse. It is a software application that helps companies control and manage the day-to-day operations of a warehouse, from the moment a product arrives at the loading dock to the moment it leaves for a customer. It is a powerful tool that helps to streamline processes, improve accuracy, and provide real-time visibility into every aspect of a warehouse’s operations.

The Power of the WMS: A Deep Dive into its Functions

A modern WMS is a sophisticated system that performs a wide range of functions, all designed to improve the efficiency and accuracy of a warehouse.

Inventory Management: At its core, a WMS is an inventory management system. It tracks every product in the warehouse, from its location to its expiration date. This real-time visibility allows companies to optimize their inventory levels, reduce waste, and fulfill orders more quickly.

Receiving and Putaway: The WMS helps to streamline the receiving process by guiding workers on where to put away new products. It can optimize the putaway process based on factors such as product size, a product’s popularity, and its expiration date, ensuring that products are stored in the most efficient location.

Order Picking and Fulfillment: The WMS is a critical tool for order picking and fulfillment. It generates optimized picking routes for workers, ensuring that they pick orders in the most efficient sequence. It can also integrate with automated systems, such as robots and conveyor belts, to further speed up the process.

Shipping and Yard Management: The WMS helps to streamline the shipping process by generating packing lists, shipping labels, and bills of lading. It can also manage the flow of trucks and containers in the yard, ensuring that they are loaded and unloaded as efficiently as possible.

The Technological Revolution: Beyond the WMS

While the WMS is the cornerstone of modern logistics, it is part of a broader technological revolution that is transforming the entire supply chain.

Robotics and Automation: The integration of robotics and automation is one of the most visible trends in modern logistics. Robots are being used to perform a wide range of tasks, from picking and packing orders to moving products from one location to another. This not only increases speed and efficiency but also reduces the risk of human error and injury.

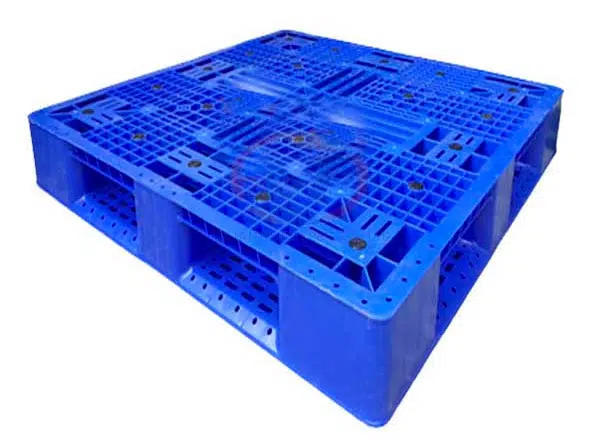

The Internet of Things (IoT): The Internet of Things is revolutionizing logistics by providing real-time visibility into every aspect of the supply chain. IoT sensors can be attached to products and pallets to track their location, temperature, and other key data points. This data can be used to optimize routes, prevent spoilage, and provide customers with real-time updates on their orders.

Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are being used to analyze the vast amounts of data generated by modern logistics systems. This data can be used to predict demand, optimize inventory levels, and identify potential bottlenecks in the supply chain. AI-powered systems can also be used to automate a wide range of tasks, from routing trucks to managing returns.

The Benefits of a Smart Warehouse

The move towards a more technologically advanced warehouse offers a number of significant benefits.

Increased Efficiency: The use of smart technologies can lead to a significant increase in efficiency, allowing companies to fulfill more orders in less time and with fewer resources.

Improved Accuracy: Automated systems and real-time data can help to reduce human error, leading to a significant improvement in order accuracy and a reduction in returns.

Enhanced Customer Service: By improving efficiency and accuracy, smart technologies can lead to a better customer experience. Customers can get their orders faster, with more accurate tracking and fewer errors.

In conclusion, technology is a powerful force that is revolutionizing industrial logistics. The WMS, in particular, is the brain of the modern warehouse, a powerful tool that helps companies to streamline their processes, improve their efficiency, and gain a significant competitive advantage. As we continue to innovate and push the boundaries of what is possible, the warehouse will become an even more intelligent, interconnected, and essential part of the global economy.